Working principle of vacuum filter

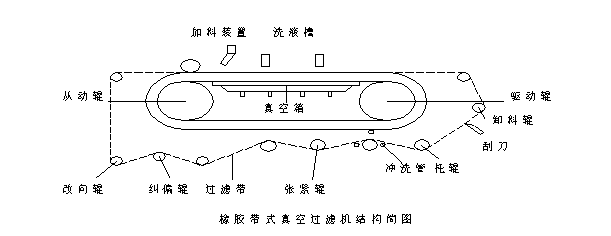

The basic working principle of the rubber belt vacuum filter: the slurry is evenly distributed on the forwardly moving filter cloth by the feeding device. Under the driving force of the vacuum pump, the filtrate passes through the filter cloth and the tape suction ditch into the vacuum box, and then From the drain hole of the vacuum box, it enters the mother liquor main pipe and the gas-water separator until it enters the collection tank for recovery. The solids are trapped on the filter cloth to form a filter cake. Due to the same direction of gravity and vacuum suction, the larger particles settle in the lower layer of the filter cake during sedimentation, and the smaller particles settle in the upper layer of the filter cake, forming a reasonable structure of the filter cake layer along with the rubber belt. Move, wash and drain for many times, and finally enter the unloading treatment at the turning point of the filter cloth. When the filter cloth is separated from the rubber belt after passing through the driving wheel, the filter cake is discharged by the discharge roller and the scraper device. After the discharge is completed, the filter cloth is regenerated through the filter cloth cleaning device. After that, the filter cloth passes through a series of filter cloth rollers, filter cloth support rollers, filter cloth rectification device, filter cloth fine adjustment device, and finally passes through the filter cloth pressure roller on the feed end assembly, and then re-covers the rubber belt to enter the feeder. The operation process of the material section, filtration, washing and draining section is completely continuous. For details, please refer to the following figure "Rubber belt vacuum filter structure diagram".