Introduction

Vertical automatic filter press is a device that separates solids and liquids from materials through the combination of high-pressure filtration and high-pressure air drying. It has the characteristics of large production capacity, high degree of automation, and low water content of the filter cake. It is widely used in mining, metallurgy, mineral processing, chemical, pharmaceutical and food industries. It is an environmentally friendly and energy-saving product.

The vertical filter press is an automatically operated filter press. Can effectively carry out solid/liquid separation. The main operating stages of the vertical filter press include: filtration, membrane extrusion, filter cake washing and compressed air drying.

working principle

The principle of pressure filtration of vertical filter press

The pressure filtration of the filter press is mainly divided into the following stages: filtration-the first squeeze-washing-the second squeeze-air drying-filter cake blanking.

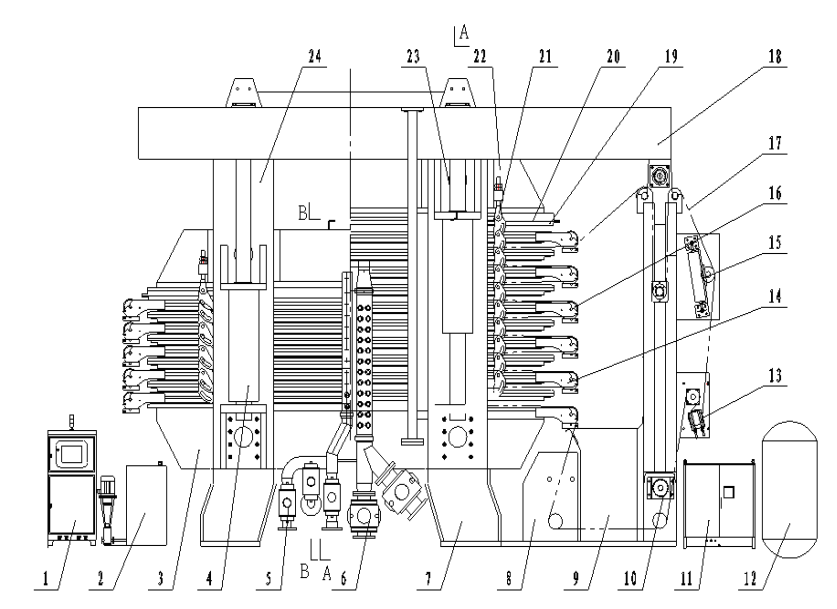

The structure of the filter press

The vertical automatic filter press is composed of plate and frame parts, piping system, hydraulic system, filter cloth system, high-pressure water station, control system, etc., each part is connected to each other and relatively independent.