Introduction

The PT ceramic disc vacuum filter is a new, high-efficiency, energy-saving, environmentally friendly, high-tech solid-liquid separation equipment integrating microporous ceramics, ultrasonic cleaning technology, and automatic control. This product is a key research project of Zhejiang Province in the "Ninth Five-Year Plan", and has been listed as a national torch plan project. It has been jointly assessed by the Ministry of Science and Technology, the State Administration of Taxation, the Ministry of Foreign Trade, the General Administration of Quality Supervision, and the State Environmental Protection Administration as a new product to be promoted by the state.

Technical characteristics

The vacuum degree is high, the filter cake drying performance is good, the production efficiency is high, and the solid recovery rate is high.

The filtrate is clear and transparent, and the working environment is clean and pollution-free.

The use of PLC degree control, high degree of automation, simple operation, stable and reliable operation; continuous operation, high equipment utilization.

Significant energy saving effect, low operating cost, no need for expensive filter cloth, less spare parts consumption, and energy saving of more than 90% compared with traditional filter equipment.

The equipment has excellent performance, compact structure, low installation cost and convenient maintenance.

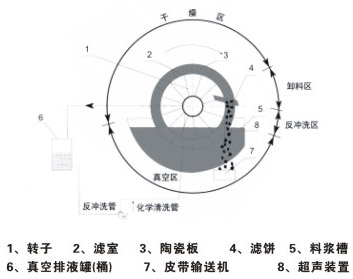

working principle

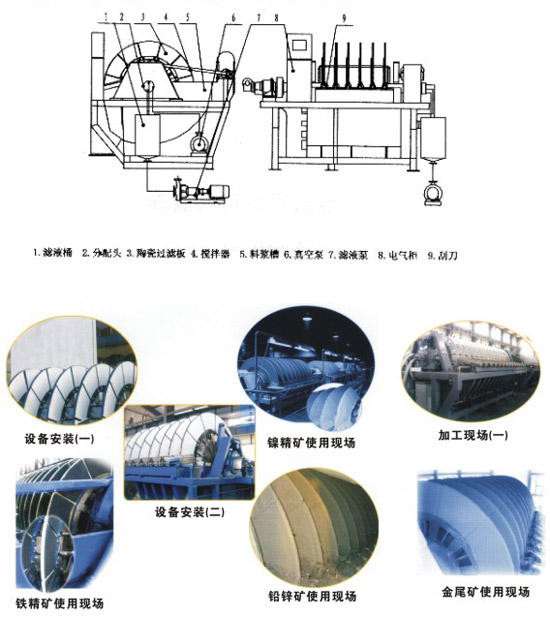

The PT type automatic ceramic disc vacuum filter mainly includes a rotor, a distribution head, a stirrer, a scraper, a slurry tank and a ceramic filter plate. Under the action of vacuum, a thicker particle accumulation filter layer is formed on the surface of the ceramic plate, and the filtrate is filtered through the ceramic plate to the distribution head and reaches the vacuum drain tank. In the drying zone, after the filter cake is dried, it is scraped off in the unloading zone and transported to the required place through the belt.

The unloaded ceramic plate finally enters the backwash zone, and the filtered backwash liquid enters the ceramic plate through the distribution head to wash the particles clogged on the micropores of the ceramic plate, and thus completes a filtration operation cycle. When the filter runs for a long time. Ultrasonic and chemical media can be used for combined cleaning to maintain the efficient operation of the filter.

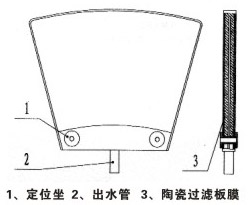

Filter plate structure function

PT series ceramic disc vacuum filter adopts new type of microporous ceramic and silicon carbide filter media. When the ceramic micropores are appropriate, due to capillary action, the micropores will not come back out of the liquid that can be contained, and the liquid will always be kept in the state of filling with air. Incompletely transparent filter plate, so energy consumption is low, and solid-liquid separation is better.

Schematic

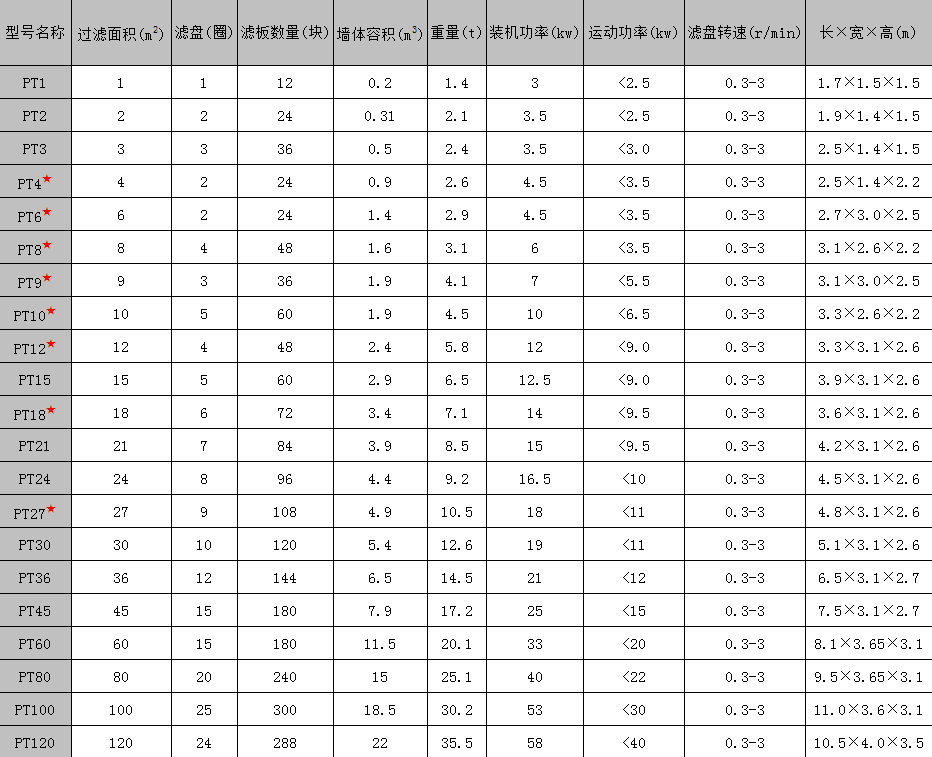

Note:★ Non-preferred series product specifications

PT series application field

At present, it has been widely used in copper, iron, gold, silver, tin, aluminum, lead, zinc, nickel, cobalt, palladium, molybdenum, chromium, inscription, sulfur, phosphorus, coal, silicon, quartz, mica, rare earth and other concentrates, Dewatering of tailings, chemical industry zinc oxide, lead oxide, zinc sulfide, electrolytic slag, leaching slag, slag dehydration and environmentally friendly sewage cement waste acid treatment, etc. The fineness of materials ranges from -200 to -450 mesh and various ultra-fine materials.

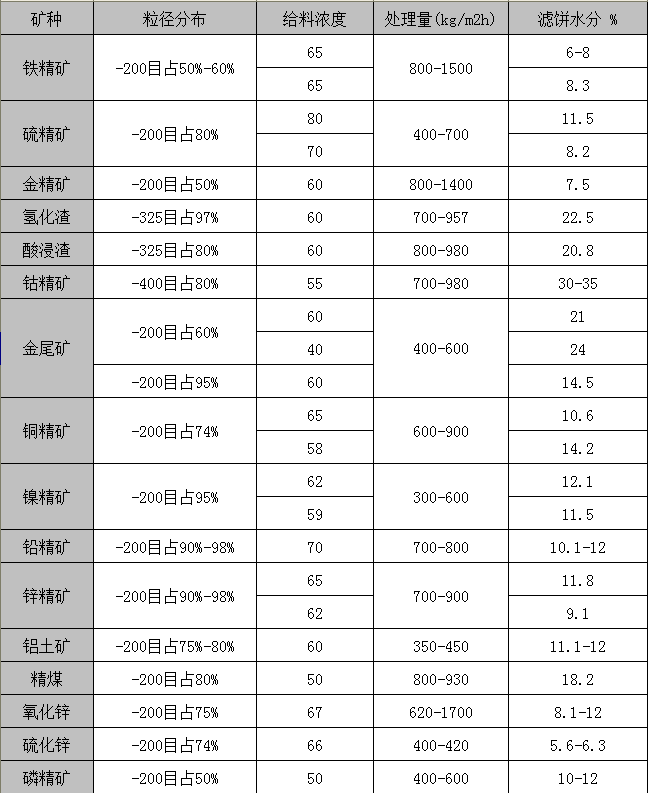

Note: Parameters may vary due to different process conditions

应用现场