one,Features:

1、With a combined structure, the vacuum filter section and the press filter can operate independently or in combination.

2、The filter cake after vacuum filtration is squeezed to make the water content of the filter cake lower.

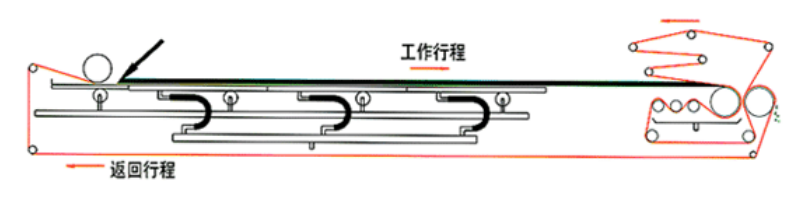

二、working principle

The vacuum belt squeeze filter is a high-efficiency separation equipment that uses filter belt as the filter medium to make full use of the material's gravity, vacuum suction, and S-shaped roller squeezing force to achieve solid-liquid separation. The integral detachable filter disc is used as the vacuum chamber, and the S-shaped squeeze roller is used as the external force. The filter belt is driven by the motor for continuous operation. The filter disc and the filter cloth operate relative to each other in a vacuum state. The material is evenly distributed on the filter belt of the vacuum filter plate through the slurry distributor. The slurry on the filter belt is filtered under the action of vacuum suction. Knowing that the vacuum filter plate touches the proximity switch position, the filter cake of the lower filter belt is in the motor Continue to run and enter the S-shaped squeeze roller while the upper filter belt squeezes the material after the material enters the S-shaped squeeze roller to reduce the moisture content of the filter cake. The filter cake after filtering, washing, re-filtering and squeezing is stripped and unloaded by the scraper device. After the filter cloth is cleaned by the automatic regeneration device, it passes through a set of support rollers and the correction device to re-enter the filter area. The filtrate in the collecting tank As the filter pan returns and discharges at the same time, the filtrate in the squeeze roller flows into the collection pan. Through such repeated suction filtration, washing, re-suction filtration, and extrusion, the purpose of solid-liquid separation is achieved in advance.