Noe, Uses and characteristics:

DNY belt type thickening press filter is a sludge dewatering equipment with high practical value developed on the basis of DY type press filter by introducing foreign advanced technology.

DNY belt type thickening and pressing filter integrates concentration and pressing. It has the advantages of high processing efficiency, good dehydration effect and low energy consumption. It is suitable for industrial production in chemical, coal, metallurgy, food, paper, urban water supply and drainage industries. Dewatering of various types of sludge and solid-liquid separation of some industrial materials. After using this equipment, the investment in the sludge thickening tank can be saved, the floor space is reduced, the sludge residence time is short, the dephosphorization effect is good, and the treatment efficiency is high.

two, Working principle

The belt type concentrating squeezing filter uses the filter belt as the filter medium, and makes full use of the gravity of the material and the squeeze force of the S-shaped roller to realize the solid-liquid separation. The flocculant is added to the sludge in a certain proportion, and it is fully stirred by the chemical-liquid mixer and flows to the filter cloth of the concentration section of the filter press. Due to the effect of the flocculant, the sludge and debris are condensed into flocs, and the moisture is under gravity. Under the action, it flows away through the filter screen, making the sludge thicker and reducing the water content. With the movement of the filter screen, the sludge enters the gravity dehydration zone of the extrusion section, and the water is further discharged, and then enters the ultra-long wedge-shaped zone. The sludge is clamped in the upper and lower filter screens to the large shaft roller, and then passes through 7 extrusions. The pressure roller and an active roller, under the action of strainer tension and repeated bending of each squeezing roller, the sludge is subjected to squeezing, bending and shearing stress, and the water contained in it is squeezed out and turned into a mud cake. Purpose of dehydration.

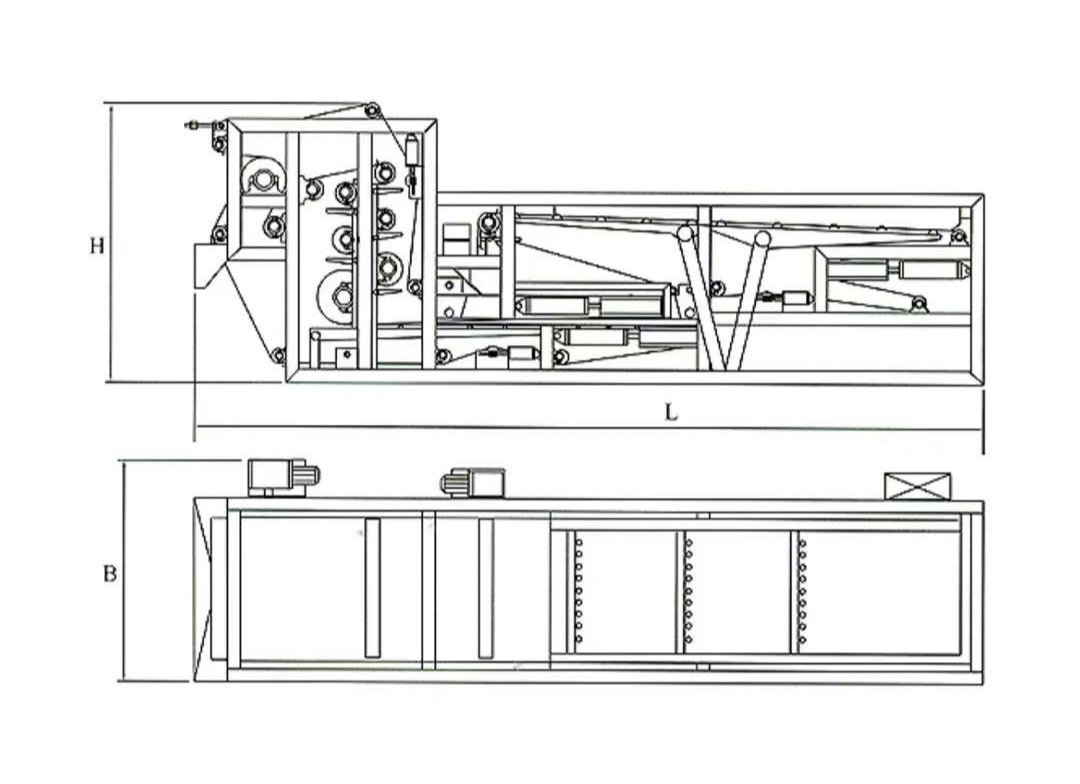

Three, host installation appearance

Fourth, the host technical parameters:

Note: Supporting equipment available

1. Sludge pump 2. Filter cloth cleaning pump 3. Dosing system 4. Air compressor 5. Flocculation stirrer, etc.

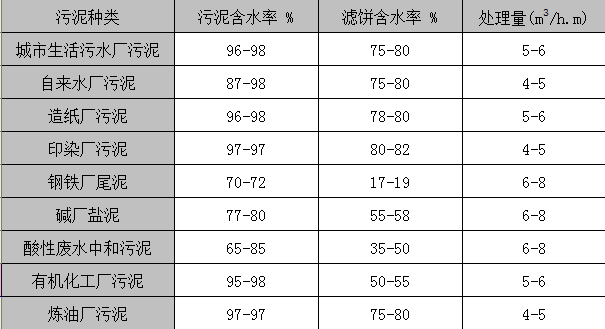

Common material dehydration effect table: