one, Features:

1、 Feeding → filtration → filter cake washing → suction drying → unloading → filter cloth cleaning is carried out continuously, equipped with PLC control, and has a high degree of automation.

2、The segmented design of the vacuum filter disc can meet the technological requirements of filtering, washing and absorbing different materials. The running speed of the filter belt adopts frequency conversion stepless speed regulation, which has a wide range of adaptability to different materials.

3、On the same equipment, multiple countercurrent washing can be used to obtain high-concentration filtrate, and co-current washing or co-current washing can also be used to obtain high-purity filter cake.

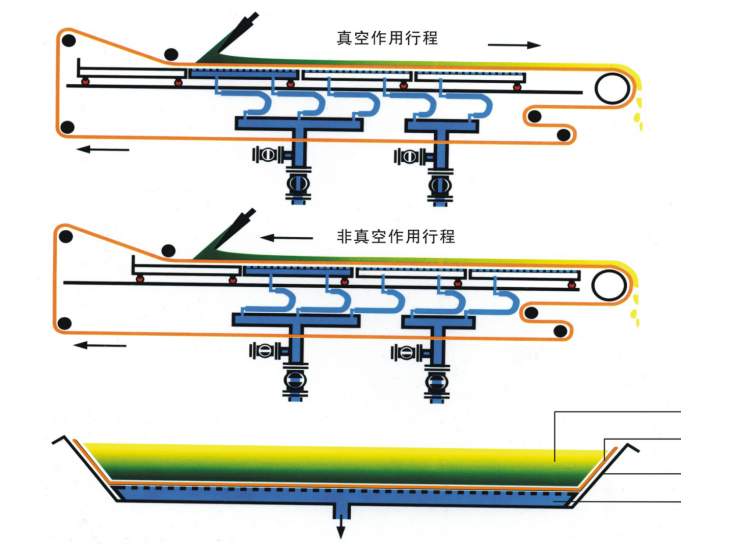

two, working principle

The continuous horizontal belt filter is a new type of filtering equipment with a high degree of automation. The machine uses a filter belt as the filter medium. The slurry on the cloth is filtered under the action of vacuum suction until the vacuum disk cuts off the vacuum when it hits the proximity switch limit device. At this time, the filter cloth continues to move forward at the same speed under the driving of the active roller, and after the vacuum disc hits the proximity switch limit device, the vacuum switching valve acts to make the filter disc release the vacuum immediately, and the vacuum filter disc is quickly dragged back to the original by the return cylinder Position, so that the vacuum filtration process is repeated again and again. After the slurry on the filter cloth is vacuum filtered, in order to better take out or recover the solution from the filter cake, perform multiple countercurrent washings to clean the filter cake. After washing, the filter cake is sucked dry by the drying zone. The content of the filter cake can vary according to different materials. If a dry filter cake is required, a drying zone can be added to the filter. Drying generally uses hot air or far infrared rays. The filter cake is washed, After being sucked dry, use the change of the curvature radius of the head wheel and the scraper device to peel and remove it.

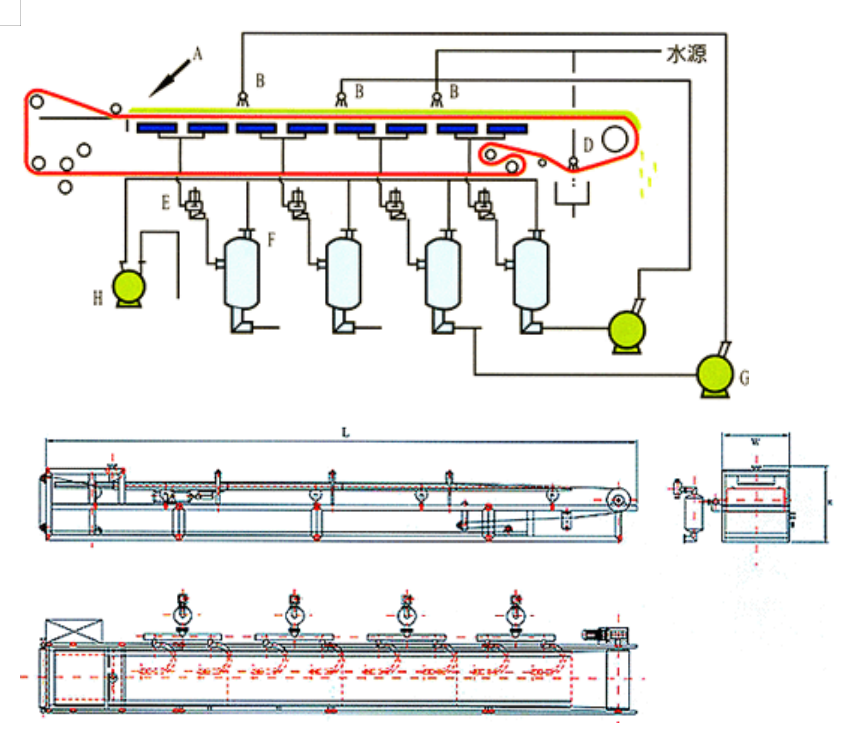

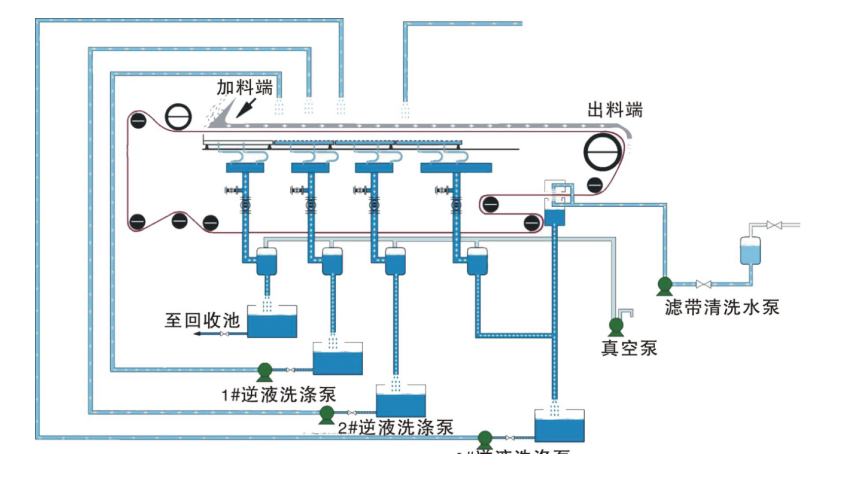

three, work flow chart

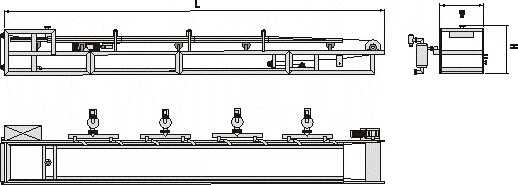

Four, Host installation shape

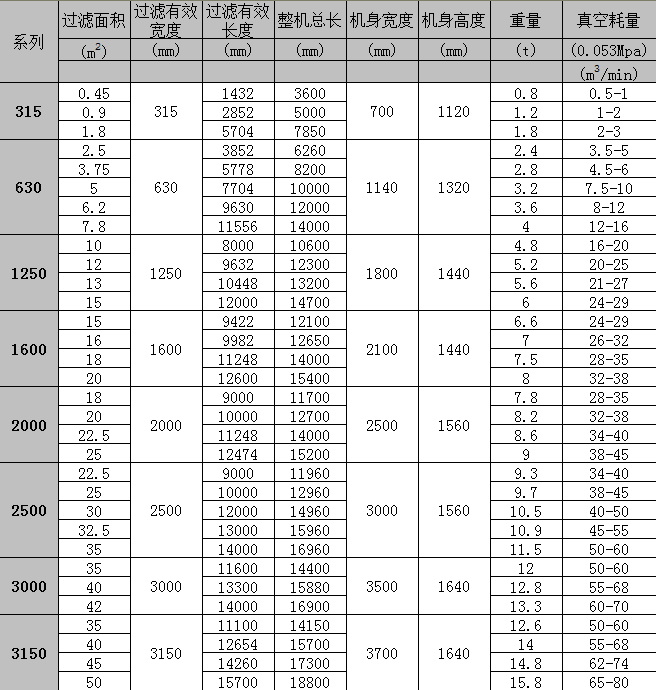

Five, specifications and model parameters

Specifications model parameters: